#002 E-Bike (V2,V3,V4)

last updated: 10/1/22

Version 5.5

The 12s 13AH battery pack was disassembled so I could use the cells elsewhere - so I had to shop around for a 13s (up from 12s) 14 AH battery for the bike.

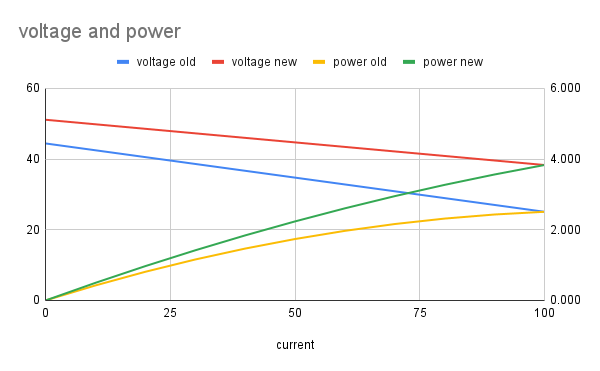

Analysis of Batteries

As well as having a higher nominal resistance, this battery also proved to have a lower internal resistance.

| Statistic | Old Custom | New Bought |

| Maximum Voltage | 4.2*12 = 50.4V | 4.2*13 = 54.6V |

| Nominal Voltage | 3.7*12 = 44.4V | 3.7*13 = 48.1V |

| Stated Maximum Current | 5C or 68A | 75A |

| Measured Internal Resistance | 0.19 Ohms | 0.12 Ohms |

| Voltage at 60A | 44.4 - 0.19*60 = 33V | 48.1 - 0.12*60 = 40.9V |

| Power at 60A | 33*60 = 1980W | 40.9*60 = 2454W |

| Power at 100A | 2540W @ 25V | 3610W @ 36V |

The bike still suffers from what I will call motor saturation - the point where the controller is powering each phase with 100% of the voltage but back EMF and winding resistance limits the current and power. To solve this problem I can increase the voltage which would require a new battery and controller or I could increase the KV of the motor.

If I double the KV of the motor, I get different performance statistics. Real world physics aside, a doubling in KV results in a doubling of RPM and a halving of torque at a given voltage and current.

However, a buck converter (aka my ESC) is a great way to trade voltage for current. MY ESC claims to output 200A per phase, so lets say 100A per phase, which is still double my phase current for the bike as it is. So, I would have the same torque but have higher RPMs... and be able to suck more power from the battery! Hopefully this is next change.

Version 5

The last issue with the bike was that the back belt consistently slipped, and the noise from the plastic

pulleys was quite obnoxious. The solution was to go from a double reduction to a single reduction. Also, the

metal pulley on the motor shaft would be the only other pulley besides the wheel pulley. The belt would now

be tightened by rotating the metal bracket that the motor is attached to around the point where it is

attached to the seat post. The lost 2:1 reduction was partially accounted for with a reduction in KV on a new

BLDC

motor, although speed did go down.

I did all those things in about two hours. Here's the result.

I have been riding the bike daily for the entirety of my sophomore year. It is powerful,

has good range and is fun to ride. It saves me a 20 minute walk to class and back three times a day

easily... I had one issue with the BMS lead wires disconnecting from one of the cells which led to that cell

not being balanced, but luckily it was savable.

Analysis

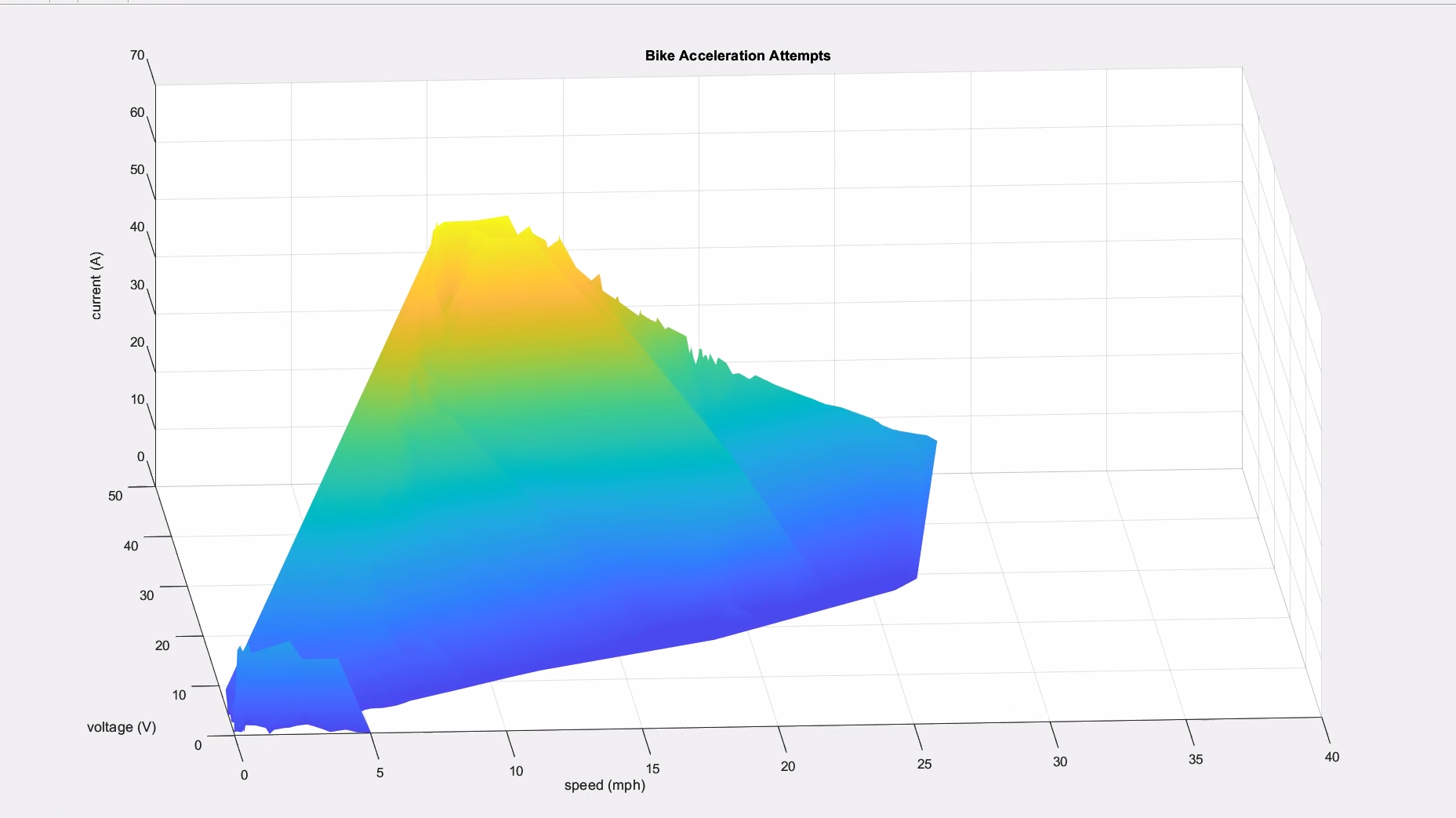

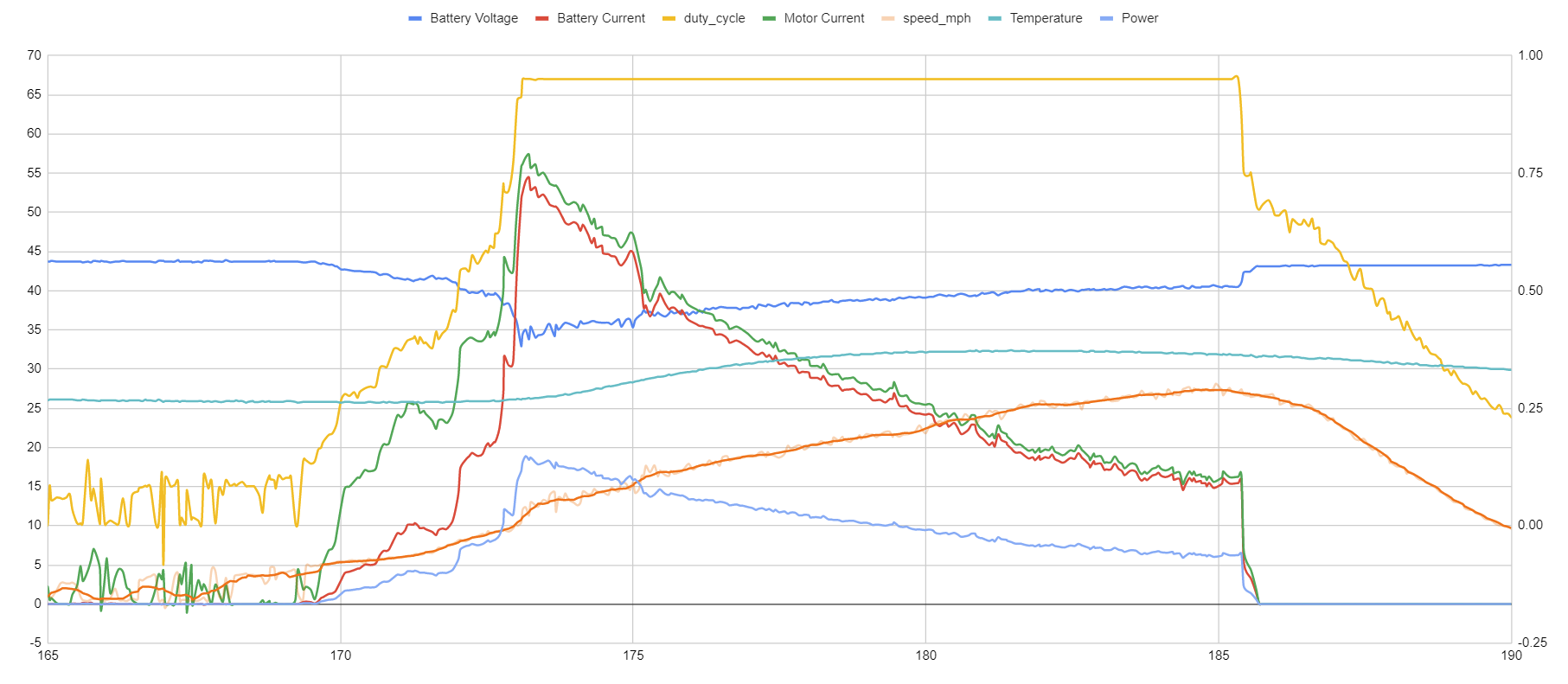

Around February 2023, I installed a cheap power meter into the handlebars to measure the voltage and current of the bike. I noticed that the bike did not draw much current above 20 mph. Utilizing the VESC's logging ability, I recoreded a bunch of fun datapoints and got to analysis.

From what I can tell, the motor for the V5 version was not selected well. At 100% duty cycle and 20 mph, the motor already only draws 30 amps. 30 amps at 44 volts is only 1.3kW... not enough!

I found this super helpful article on motor selection from Benjamin Vedder, the creator of VESCs. It points out that for motors of equivalent size changing KV does not effect waste heat per unit of torque. My goal is higher power and higher speed with the same belt geometry. If I were to double the motor KV, I could operate at my same performance with double my current at half my voltage. The reality of speed controllers means that no additional load is required from battery. (200% amps at 50% voltage is 100% power). But, I can use 100% of my voltage, and keep higher currents during higher RPMs. This led to Version 6.

Version 4

The new battery is much better. I fabricated it myself out of the same yellow cells (QB26800) I used in my car. I can go three times as far and get to speeds that are completely unreasonable for a bike. It has a BMS and is lithium ion.

Version 3

- Upgraded from $40 cheap no-brand ESC(7s, 125 Rated Motor Amps) to 90 dollar VESC6.7 Single (12s, 200 Burst Motor Amps).

- Switched the zip--ties holding the rear pulley to the spokes out with U-Bolts and nuts.

- Switched the 3/16 inch aluminum for the motor bracket out for 5/16th aluminium of a higher grade to reduce bending.

- Removed the current sensor, screen, and speed sensor for greater weather reliability.

Version 2

The premise of V2 rests on one major issues with V1: It just wasn't strong enough. For the smaller upper timing belt, the forces were all conveyed into the single bracket that both the motor and hex bearing were bolted into. The larger belt, however, had a single aluminum plate that only balanced out forces from one axis on one side of the axle. Version two is based on the idea that two brackets, both secured in two places on the E-Bike, provides enough rigid force in order to be able to turn the motor up to full power, compared to the time-based spool-up I had previously.